ATLAS ITk

Entwicklung von flexiblen PCBs für ITk-Module

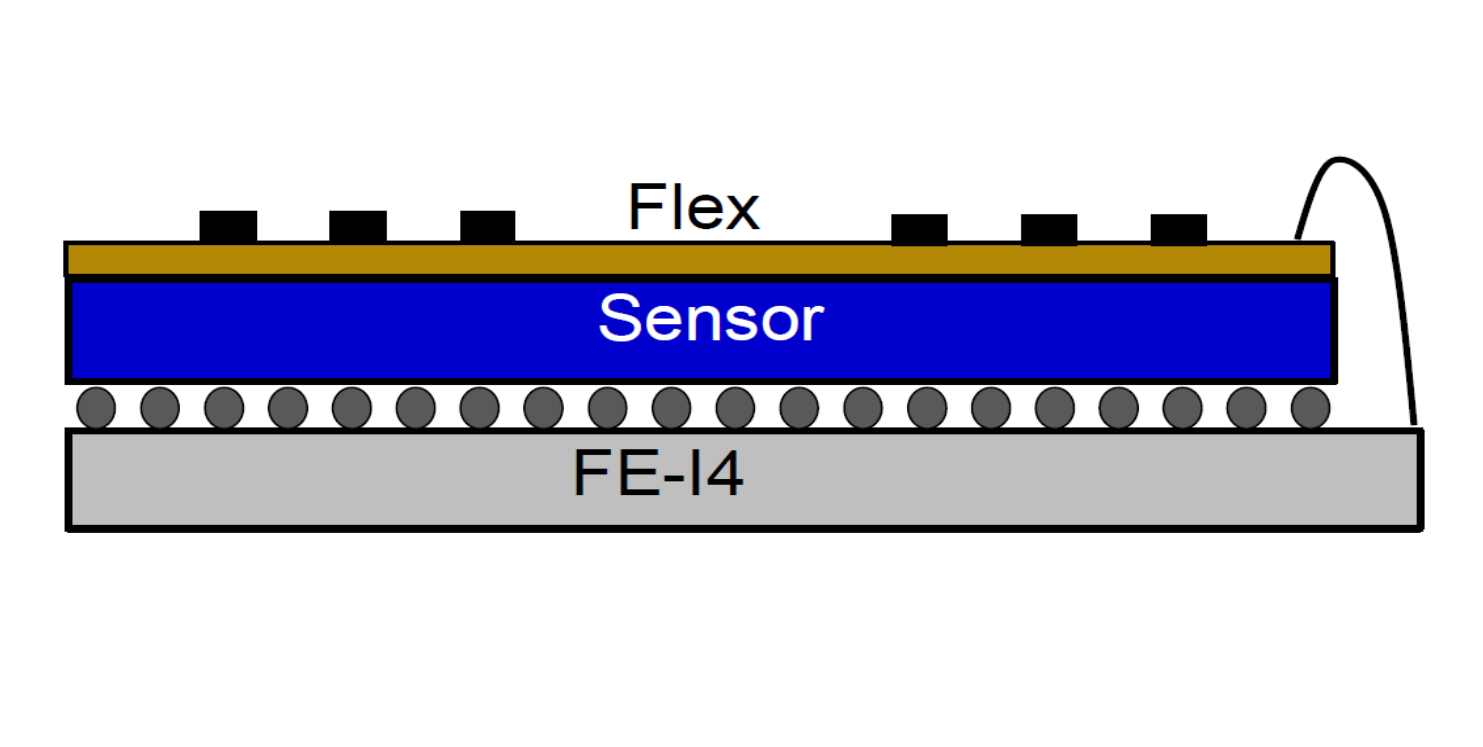

Unsere Gruppe entwickelte das Design der flexiblen PCBs für die Prototyp-Version des Hybrid-Moduls, welches mit FE-I4B-Chips ausgestattet war. Das Hybrid-Modul (Abb. 1) besteht aus einem flexiblen PCB, genannt Flex, einem auf das Flex geklebten Sensor, sowie Front-End-Halbleiter ("FE-Chips"). Die FE-Chips sind via "Bump-Bonding" mit dem Sensor und mittels Drahtbonden mit dem Flex verbunden. Diese Aufbauweise gewährleistet die Signalweiterleitung and die Hochspannungsversorgung des Sensors. In unseren Laboren haben wir Module für den Hauptstrukturdemonstrator gebaut und getestet. Der Demonstrator setzt sich aus dem sog. Longeron (d.h. der Hauptstruktur aus Kohlenstoff), den Pixel Quad- und Dual-Modulen, einem Kühlsystem und einer radioaktiven Quelle für Testzwecke zusammen.

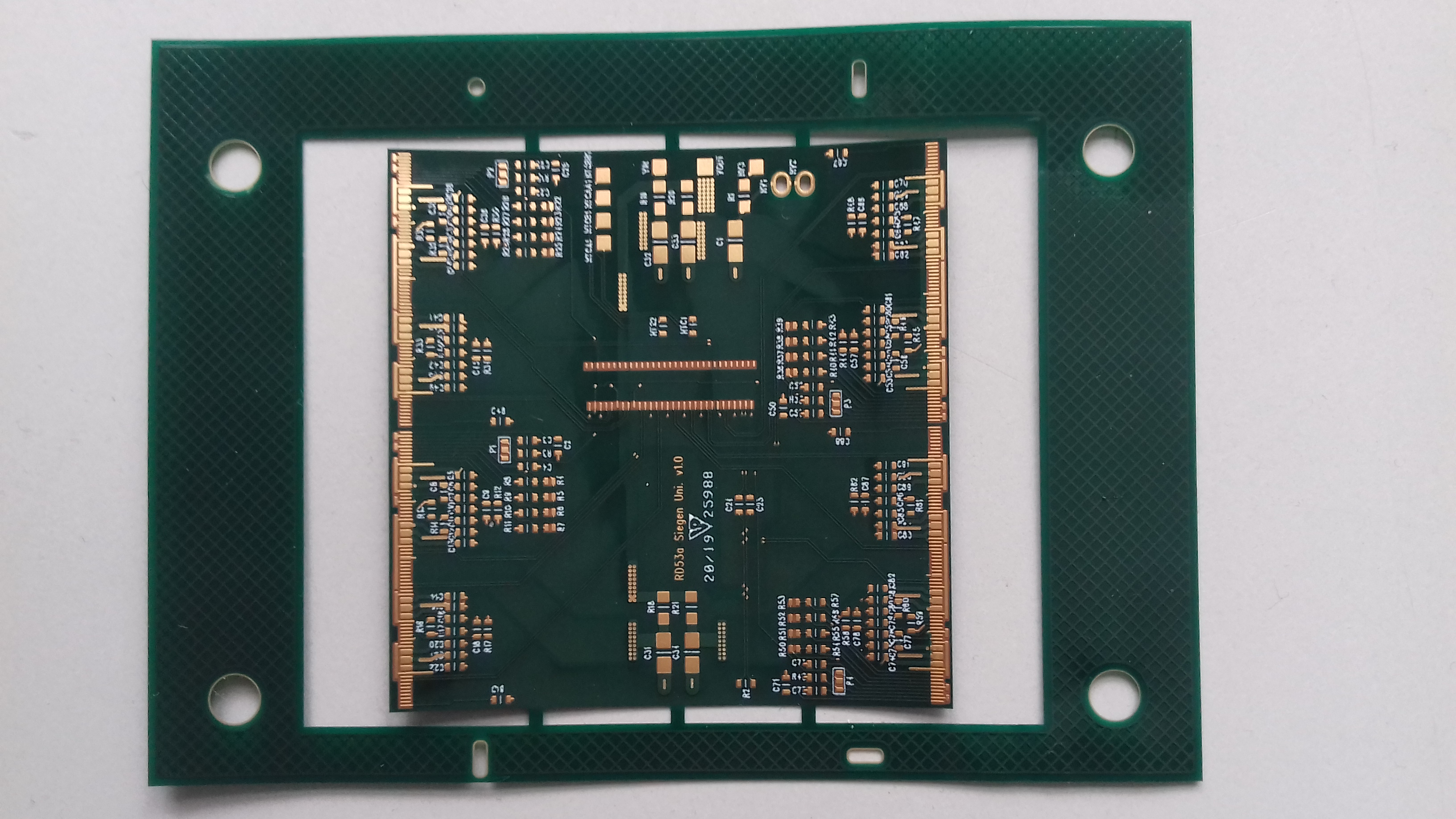

Für das FE-I4B-Demonstrationsprogramm entwickelten wir einen Flex für Quad- und Dual-Module (Abb. 2), und bauten und testeten Quad-Module, welche mit RD53A-Chips bestückt sind. Der RD53A-Chip war die nachfolgende Prototyp-Version, die von der RD53 Kollaboration entwickelt und mit der 65-nm-Technik produziert wurde. Diese Module sind Teil des am CERN befindlichen Demonstrators, für welchen neben RD53A- auch RD53-Chips (später als ITkPixV1-Chips bezeichnet) verwendet wurden.

Weitere Details zum Siegener Flex-Design für Pixel-Module und dem Bau und Testen von Prototyp-Modulen sind hier verfügbar.